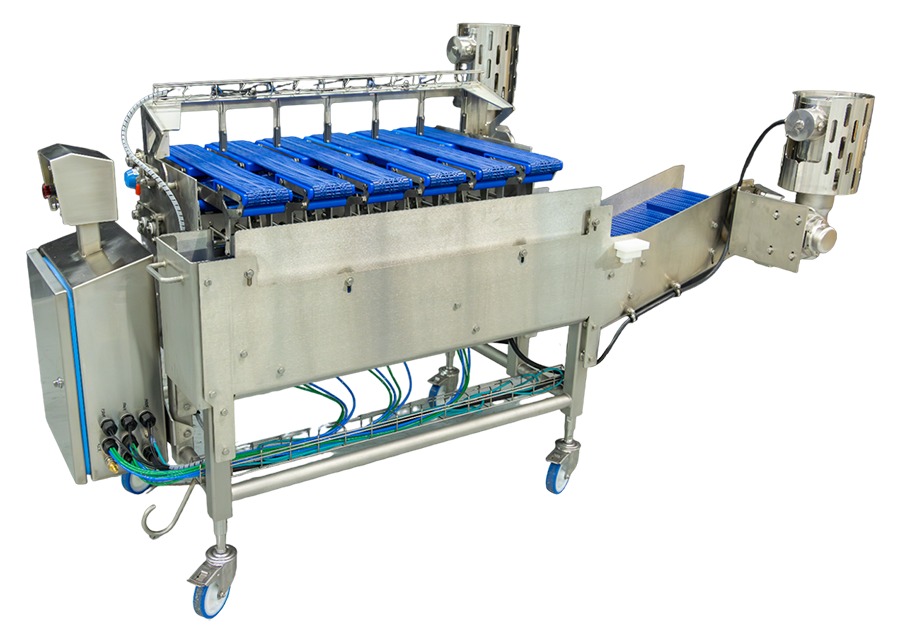

Automated Quality Control Systems

The Forpak Reject System automates the removal of discrepant product, or product that must be diverted due to downstream issues. The system will automatically reject individual items for excess height, and can divert all product in the event of downstream stoppages.

Advantages of The Reject Module

The Reject Module was engineered to improve hygiene and reduce maintenance time. The module is able to be removed without removing the belting…saving time and effort.

Features

Better overall hygienic design

Easy, tool-free maintenance

Reduced need for teardown for cleaning and maintenance

Reduced setup times

Ergonomic design reduces effort required for installation and removal of the Reject Module

Weight reduced 50% to 23 lbs.

Flat belt path vs. sloped provides a smooth transition of product or stacks

Motion components no longer need to be moved for installation and removal of the Reject Module

Tool-free location mechanism of the Reject Module

Extends life of belts and sensors

Machine Vision available for most products

PDF Downloads

ENG Reject System

Power Requirements

Domestic - 230/460 VAC 3 phase

International - 380 to 600 VAC